- HYDRAULIC WIRE STRAIGHTENING AND CUTTING MACHINE

Hydraulic wire straightening and cutting machine

Round rod straightening and cutting machine

Low carbon wire straightening and cutting machine

Automatic hydraulic wire straightening cutting machine

Hydraulic rebar straightening cutting machine

- 01. Introduction of hydraulic wire straightening and cutting machine

- Applications: smooth round steel plate, cold rolled ribbed steel bars, hot rolled ribbed steel bars, the straightening and cut-off.

Good straightening effect: Straightening ratio ≤ 3mm / m, the surface almost no scratches, no distortion.

Intelligent control: PLC programmable control, cut-length accuracy and can be adjusted, automatic counting, the number of downtime.

Can used to straight the new Ⅲ grade steel, the advanced way to ensure the straightening does not damage the cross-rib reinforced, without causing longitudinal ribs to reverse, the surface wear.

Cutting method: hydraulic cutting, low noise, less wearing parts.

Mechanical wire straightening and cutting machine is mainly used to straight and cut the wire to feed in the fencing mesh welding machine, basement mesh welding machine.

- 02. Main parameter

-

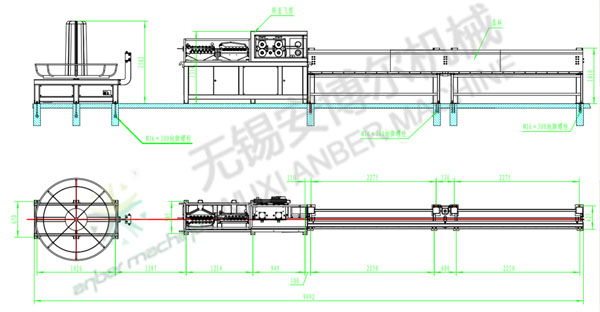

Collecting tableModelABE-HT3/6ABE-HT4/8ABE-HT6/14Wire Dia.Φ3-Φ6mmΦ4-Φ8mmΦ6-Φ14mmTotal power11+3kw15+4 Kw18.5+5.5kwCutting length1-12 m, or according to customer’s requirementStraightening ratio≤2 mm/mMax. speed30m/minCutting tolerance±3 mmRoller diameterΦ140mmOverall sizeMain part2700×800×1250mmHydraulic station1050×900×1120mmCollection table12000×600×1050mm

Length: 3-12m, can set according to customer’s requirement