- 3D TRUSS GIRDER WELDING LINE

- Home >Our products

3D Truss girder welding machine

lattice girders welding machines

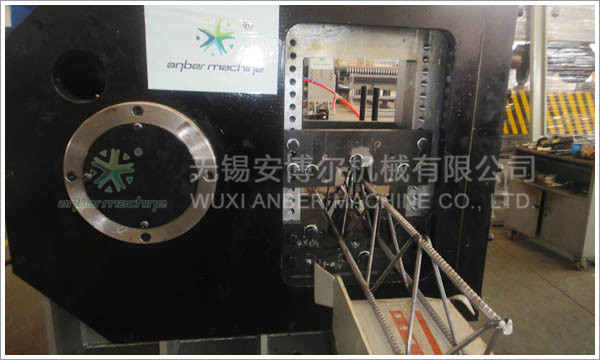

Welding system

Wire recoiler

Cutting system

- 01. DESCRIPTION

- 3D truss girder welding machine, also named lattice girder welding line, the Lattice girder welding machines produce standard lattice girders, thrust girders and wall girders.

- 02. CHARACTERISTICS

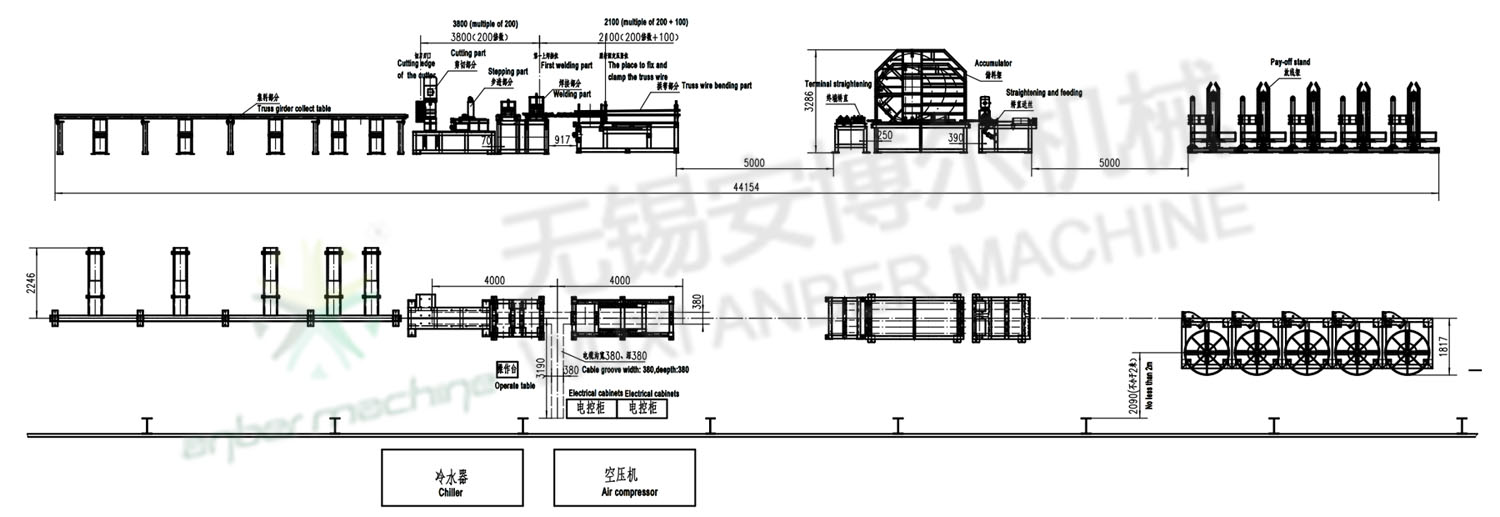

- 1. Layout plan: Line wire pay-off → Line wire straightening unit → Rod bending unit → Welding system → Cutting system → Truss girder collector

2. Only need one operator to control, it has been widely applied in the area of high speed railway and building structure, etc.

3. Controlled by servo motor and PLC, which can promise the machine work stable and high accuracy.

4. It is full auto collected and produced, no need many workers, and it is high efficiency.

5. Apply famous brand elements and parts, can service for long time and work stable.

- 03. PARAMETER

- Material type:FeB44K, FeB32K, FeB38K

(weldable)

Unitary yield stress :Max 600N/mm ²

Unitary tensile stress :Max 700N/mm ²

Elongation:>14%

Longitudinal wire diameter (upper): 8mm–12mm

Longitudinal wire diameter (lower): 8mm–12mm

Diagonal wire diameter:5mm– 8mm

Production rate (maximum) :10m/min

Girder height mm :144

Girder internal base width: 80mm

Pace/stroke: 400mm/weld

Diagonal spacing:200mm

Girder length :6m or at customer’s requirement

Cutting length :Multiples of 200mm