- PILE CAGE WELDING MACHINE

- Home >Our products

pipeline reinforce mesh welding machine

pile cage welding machine

tubular roll welding machine

cage welding machine

The products

- 01. ABGZ-300/1200 mode cage welding machine

- This pipeline reinforce mesh welding machine is a special-purpose welding machine of reinforcement frames for superstrength tubular concrete piles with a diameter of 300、600、800、1200mm.It can widely be used in welding auto stressed or prestressed reinforcement frames either by pretension or posttension.The machine can handle large-diameter principal steel bars with little loss in their strength and log-length frames without twisting and warping,thus ensuring high overall performance of the frame.The pitch of the frame can easily be adjusted according to requirement and framing is time different .Being sable in its performance and easy in its maintenance,the machine is the first of its kind in China,utilizing exclusively domestic parts.it is used in the fundamental construction projects,such as harbors,bridges,quays,high rises and workshop buildings.

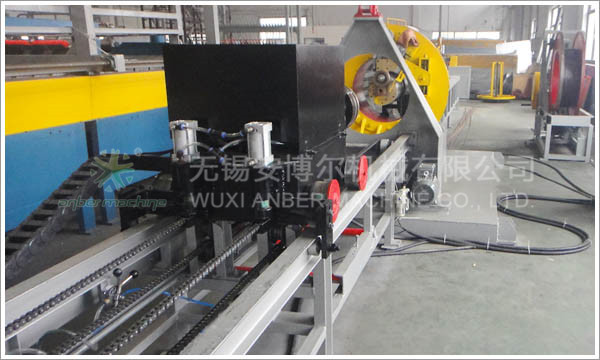

- 02.ABGZ100/3000 model concrete pipe reinforcement mesh welding machine

- The Concrete Pipe Reinforcement Mesh welding machine are widely used for automatic seam welding of reinforcement frames of concrete pipes.such as sewer,drainpipes,pit shaft oil and gas pipes.The machine employs advanced technologies of silicon controlled rectifier and photo electronics control to such a degree that the labor intensity is greatly reduced and the production efficiency is greatly reduced and the production efficiency is greatly raised.The frames produced have uniform pitch and high rigidity.It is also capable of producing special reinforcement frames of specifications and requirements provided by user

- 02.ABGZ110/230 model Pile cage welding machine

- The pile cage welding machine is used for production of concrete poles.The welding machine is with a speed regulating motor pulls the longitudinal bars and the pile cage welding block makes the welding while the circumferential steel bars wind round the longitudinal bars.The main transformer generates a strong current through the electrode welding block to make the crossed longitudinal and circumferential bars rise quickly in temperature until they become plastic and then the contact points are solidly welded under the pressure of the welding block.The pole welder has such advantages as high efficiency,quick forming,no twisting,high strength,labor and time saving and reduced intensity of labor,etc. The welder is composed two major parts of mechanical drive and electrical control.