- SWG12D-1 STEEL BAR STIRRUP BENDER

- Home >Our products

CNC steel bar stirrup bender

steel bar stirrup bender

CNC stirrup bender

stirrup bender

stirrup bender

- 01. CHARACTERISTICS

- Automatic wire feeding system to ensure highly dimensional accuracy;

Movable air compressor design, to ensure better cooling effect, easy transportation and installation;

Split, multifuctional blade design (patented) to reduce consumption costs;

Automatic double wire intake system with more bending shapes to bring high processing efficiency;

High power servomotor to ensure bending bar accuracy;

The intelligent fault identification alarm system with more convenient maintenance;

Aerodynamic design observation door with easy, safe and fast adjustment and maintenance;

Heavy-duty design line planes, equipped with a brake and buffer device, preventing chaotic lines caused by downtime;

High degree automation with large storage capacity of 400 prestored processing geometric graphics for instant use;

Straightening wheels, hauling wheels and metering wheels made with special steel materials to ensure longer service life and lower operating costs; Touch-screen console to ensure easy and fast operation;

All electrical parts are from Schneider, SIMENS, ABB or OMRON brand to ensure the service life;

Automatic splicing device with one operator for one machine (optional).

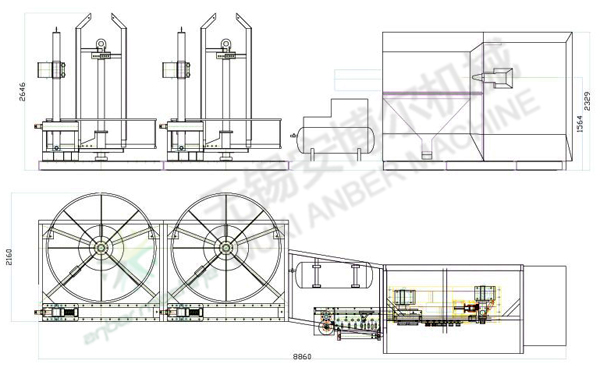

- 02. COMPOSITION

- Pay-Off; Pre-adjusted assembly; Hauling assembly; Straightening assembly; Observation automatic door; Shear assembly; Bending assembly; Console; Bending arm telescopic cylinder; Bending servomotor; Shear motor; Hauling servomotor; Air compressor; Electric control cabinet .

- 03. PARAMETER

- Single wire processing capacity: Φ5 - 12 mm

Double wire processing capacity:: Φ5 - 10 mm

Max bending angle: 180°

Max bending speed: 80-1050°/sec

Max pulling speed: 75-110 m/min

Max length of the stirrup: 1000 mm

Min length of the stirrup side: 110 mm

Length tolerance: ±1 mm

Bending tolerance: ±1°

Average air-compressed consumption: 6 l/min

Average electric power consumption: 6 - 8 Kw/hour

Labeled electric power: 32 Kw

Bending direction: bi-direction

Working condition: -5°-40°